Products

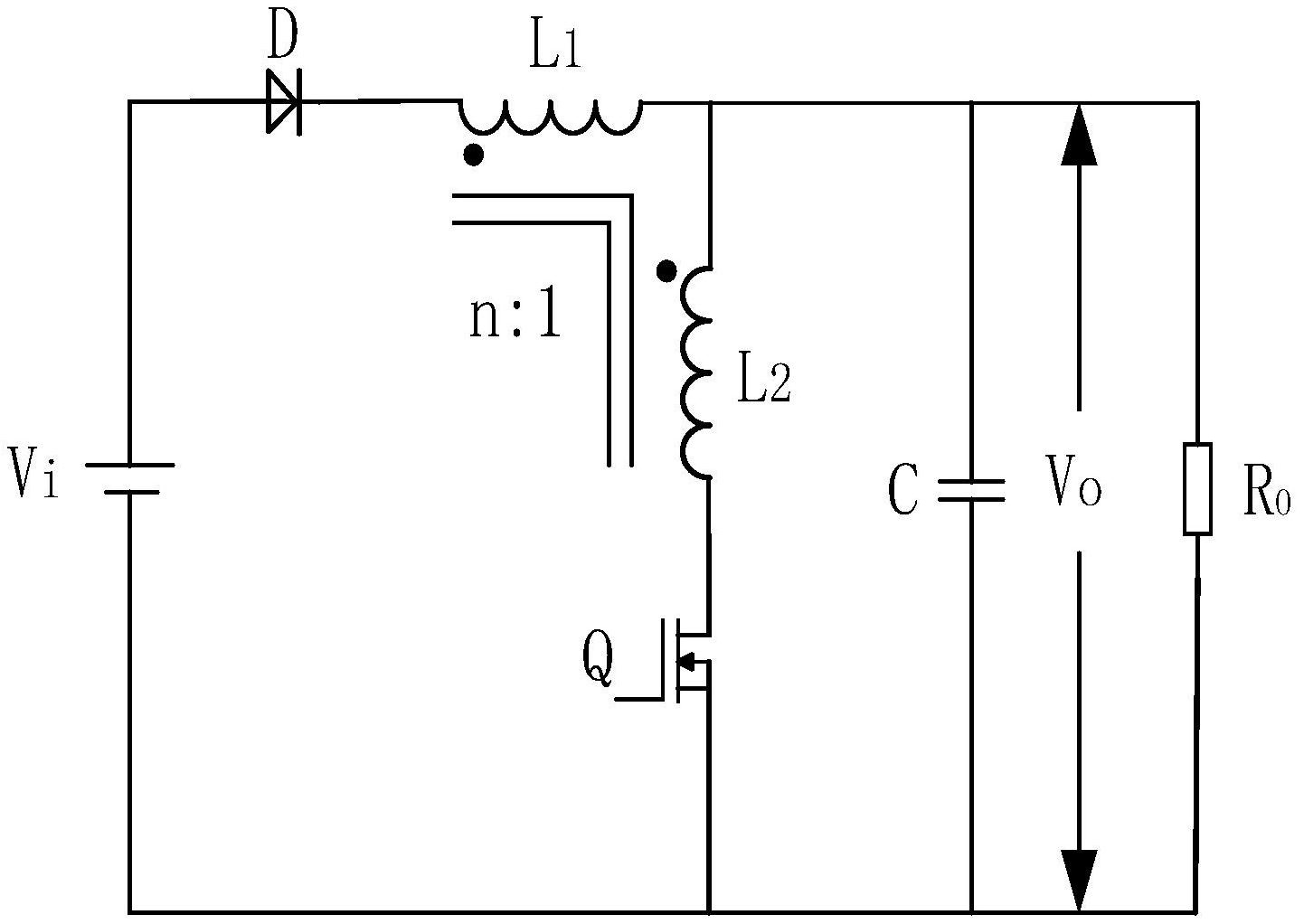

Boost Inductor (Boosting Voltage Converter)

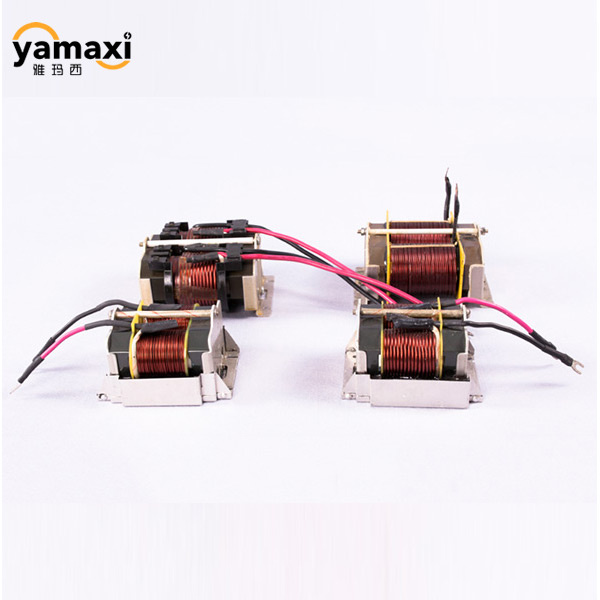

The types of boost inductors include:

1. According to structural classification, inductors can be divided into wire wound inductors and non wire wound inductors.

2. According to the installation method, there are patch type inductors and plug-in type inductors.

3. According to the application, inductors can be divided into oscillation inductors, correction inductors, picture tube deflection inductors, resistive inductors, filtering inductors, isolation inductors, compensated inductors, etc.

The detailed advantages are shown in below:

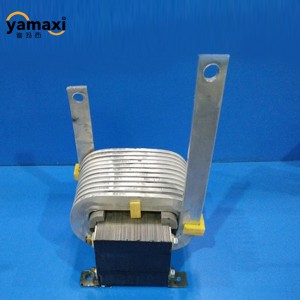

(1) The annular magnetic core and flat vertical winding wire have good electromagnetic coupling, simple structure and high production efficiency and good consistency of parameters;

(2) Because flat copper wire is mostly used, skin effect can be overcome, resulting in high working frequency and high power density, with the frequency between about 50kHz and 300kHz;

(3) The vacuum sealing process has excellent heat dissipation characteristics, small components with a high surface area volume ratio and a very short heat channel, which is convenient for heat dissipation;

(4) High efficiency, the magnetic core structure of the special geometric shape can effectively reduce the core loss;

(5) Small electromagnetic radiation interference. Low power loss, low temperature rise, high efficiency;

(6) Block core structure, to meet the customer more appearance performance requirements.

(1) Adopt a variety of magnetic material combinations, take the advantages and disadvantages of different materials, to compensate each other mutually, and get excellent cost-effective products;

(2) The electrical performance of the products is stable, the manufacturing process is simple, and the production efficiency is high;

(3) The products have small size, low power consumption, low temperature rise and low cost;

(4) The products have high efficiency and low noise.

Widely used in home appliances (air conditioners), photovoltaics, UPS power supplies, smart grids, smart inverters, high-power power supplies, medical equipment, etc.